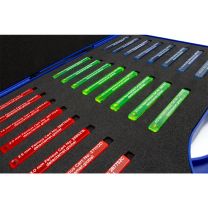

Calibration Test Pieces

Calibration of metal detectors and x-ray inspection systems in the food industry is a fundamental step in maintaining product safety, quality assurance, and regulatory compliance. These systems are designed to detect contaminants and defects, and their calibration ensures optimal performance. Click to read more...

- Accuracy and Sensitivity: Calibration ensures that metal and x-ray detectors accurately detect contaminants, minimizing the risk of false positives (incorrectly identifying a contaminant) and false negatives (missing an actual contaminant). Proper calibration ensures that even small or low-density contaminants are detected.

- Compliance with Food Safety Regulations: Food safety agencies, such as the FDA, USDA, and others, mandate that food manufacturers maintain high safety standards. Calibration ensures that metal and x-ray detectors meet these requirements, reducing the risk of non-compliance, fines, and product recalls.

- Adaptation to Operating Conditions: Factors like temperature, humidity, electromagnetic interference, and environmental changes can affect detector performance. Calibration helps these systems adapt to varying conditions, maintaining reliability and accuracy.

- Consistency Across Production Runs: Different production runs may involve varying product types, shapes, and densities. Calibration ensures that metal and x-ray detectors maintain consistent performance across these variations, leading to more reliable results.

- Quality Assurance and Product Integrity: Calibration supports quality assurance by ensuring accurate detection of contaminants and defects. This is crucial for maintaining product integrity, reducing customer complaints, and preserving a company's reputation.

- Preventing Equipment Wear and Tear: Regular calibration can identify issues in the detector's operation, preventing excessive wear and tear and extending the equipment's lifespan. This proactive maintenance approach reduces the risk of unexpected breakdowns or costly repairs.

- Supporting Auditability and Documentation: Calibration provides a traceable record of the detector's performance over time. This documentation is crucial during audits and inspections, demonstrating that the company follows industry best practices and maintains a robust food safety program.

- Reducing Production Costs and Risks: Proper calibration reduces false alarms and product rejects, which can be costly in terms of wasted materials and production delays. Accurate detection of contaminants also lowers the risk of expensive recalls and legal liabilities.

- Ensuring Consumer Safety and Trust: The ultimate goal of calibration is to protect consumers from harm. By ensuring metal and x-ray detectors function correctly, food companies reduce the risk of contaminated products reaching the market. This, in turn, enhances consumer trust and loyalty.

Calibration of metal detectors and x-ray inspection systems in the food industry is a fundamental step in maintaining product safety, quality assurance, and regulatory compliance. These systems are designed to detect contaminants and defects, and their calibration ensures optimal performance.

- Accuracy and Sensitivity: Calibration ensures that metal and x-ray detectors accurately detect contaminants, minimizing the risk of false positives (incorrectly identifying a contaminant) and false negatives (missing an actual contaminant). Proper calibration ensures that even small or low-density contaminants are detected.

- Compliance with Food Safety Regulations: Food safety agencies, such as the FDA, USDA, and others, mandate that food manufacturers maintain high safety standards. Calibration ensures that metal and x-ray detectors meet these requirements, reducing the risk of non-compliance, fines, and product recalls.

- Adaptation to Operating Conditions: Factors like temperature, humidity, electromagnetic interference, and environmental changes can affect detector performance. Calibration helps these systems adapt to varying conditions, maintaining reliability and accuracy.

- Consistency Across Production Runs: Different production runs may involve varying product types, shapes, and densities. Calibration ensures that metal and x-ray detectors maintain consistent performance across these variations, leading to more reliable results.

- Quality Assurance and Product Integrity: Calibration supports quality assurance by ensuring accurate detection of contaminants and defects. This is crucial for maintaining product integrity, reducing customer complaints, and preserving a company's reputation.

- Preventing Equipment Wear and Tear: Regular calibration can identify issues in the detector's operation, preventing excessive wear and tear and extending the equipment's lifespan. This proactive maintenance approach reduces the risk of unexpected breakdowns or costly repairs.

- Supporting Auditability and Documentation: Calibration provides a traceable record of the detector's performance over time. This documentation is crucial during audits and inspections, demonstrating that the company follows industry best practices and maintains a robust food safety program.

- Reducing Production Costs and Risks: Proper calibration reduces false alarms and product rejects, which can be costly in terms of wasted materials and production delays. Accurate detection of contaminants also lowers the risk of expensive recalls and legal liabilities.

- Ensuring Consumer Safety and Trust: The ultimate goal of calibration is to protect consumers from harm. By ensuring metal and x-ray detectors function correctly, food companies reduce the risk of contaminated products reaching the market. This, in turn, enhances consumer trust and loyalty.

Detectamet Australia (English - $ AUD ) Click here to change your currency, region and language.

Detectamet Australia (English - $ AUD ) Click here to change your currency, region and language.